Heat exchangers are the unsung heroes of thermal management, quietly ensuring systems from HVAC to industrial processes run smoothly. As someone who’s spent years tinkering with these devices, I’ve seen the field evolve dramatically, especially with the rise of microchannel heat exchangers. But how do they stack up against traditional designs like water coil systems? Let’s break it down, comparing the two technologies side by side on design, performance, and daily use to allow you to glimpse which might be ideal for your needs.

Knowing the Fundamentals

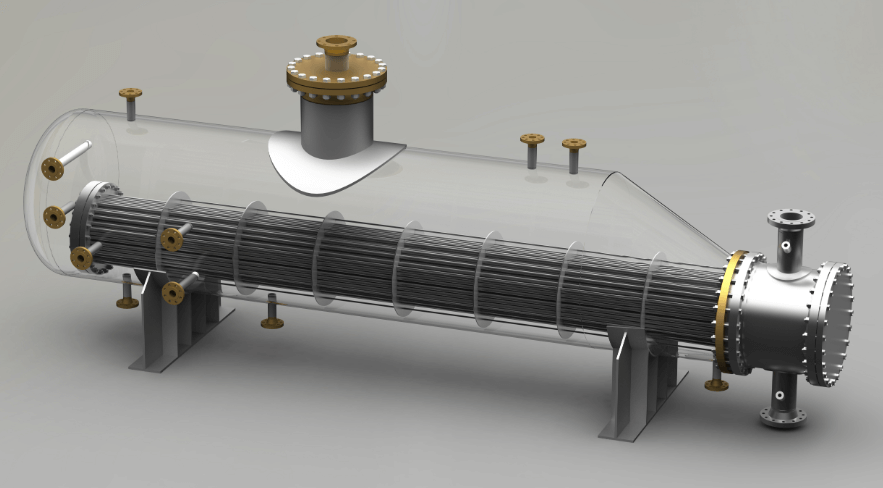

Old-fashioned heat exchangers, such as the water coil type, have been the standard of thermal management for a long time. They work with big pipes—albeit copper or steel pipes on occasion—coiled up and through which a liquid like water or refrigerant is pumped. The coils transfer heat from the fluid to the surrounding air or to another fluid. They’re robust, reliable, and familiar to anyone who’s had experience in industrial cooling or HVAC.

Microchannel heat exchangers, nonetheless, are a newer generation. They use flat, multi-port aluminum tubes with extremely small channels—sometimes a fraction of a millimeter wide—to maximize heat transfer in a small envelope. The channels create a lot more surface area for heat transfer, and therefore are extremely efficient. The water coil in older units is typically larger, while microchannel systems emphasize slenderness and efficiency.

Design Differences

The most apparent variation is in size. Traditional water coil heat exchangers are heavy and bulky with copper fins and tubes. This is a disadvantage in cases where space is a concern, like in modern data centers or in compact HVAC units. Microchannel exchangers are light and compact because they consist of aluminum and have a small channel size. They are a popular choice in space-limited situations.

Material choice also enters the picture. Copper used in water coil systems is durable but prone to corrosion under harsh conditions and requires proper maintenance. Aluminum employed in microchannel structures is corrosion-proof and lightweight, loading structures less. However, the fine-scale channels in microchannel systems are more likely to clog with debris or poor-quality water, which requires high-quality filtration.

Performance and Efficiency

For heat transfer, microchannel heat exchangers tend to be more efficient than their conventional cousins. The tiny channels cause flow to be turbulent, which is more efficient at transferring heat. What this translates to is that a microchannel system can deliver the same cooling or heating as a water coil system with less material and refrigerant. In my experience, this efficiency carries over to reduced energy bills—oftentimes 20-30% in well-designed systems.

Inconventional water coil systems, while less efficient on a per unit capacity basis, are not to be ignored. They handle greater fluid volumes and are less sensitive to flow variation, making them ideal for use in applications with sporadic thermal loads, like industrial processes. They’re also forgiving in applications where upkeep may be sporadic because their greater tube dimensions are less prone to clogging.

Energy efficiency isn’t just about heat transfer—it’s also about system design. Microchannel systems often require less refrigerant, reducing environmental impact and operational costs. However, water coil systems can integrate seamlessly with existing infrastructure, avoiding the need for costly retrofits. Choosing between the two often depends on whether you’re building from scratch or upgrading an older system.

Practical Applications

Microchannel heat exchangers are the go-to option for new applications like data center cooling, auto air conditioning, and mini HVAC systems. They are efficient and can be very compact, which is why they are suited for applications where space and energy savings are critical. For example, in a data center, a microchannel system can be used to cool high-density server racks without occupying valuable floor space.

Traditional water coil heat exchangers still dominate in heavy-duty applications. Think large industrial chillers, district heating systems, or older buildings with legacy HVAC setups. Their robustness and ability to handle high thermal loads make them a reliable choice where efficiency isn’t the sole priority. I’ve seen water coil systems keep massive factory cooling systems running for decades with minimal fuss.

Challenges and Trade-offs

Microchannel systems are not perfect. Their highly efficient, narrow channels are a double-edged sword: clogging is an issue if filtration is not optimum. They are more costly at the outset due to advanced manufacturing processes as well. Cost-sensitive projects will find this a stumbling block, though cost savings in energy over the long term normally offset the greater upfront cost.

Traditional water coil units, while being cheaper to purchase, may prove to be less efficient and larger, thus having greater costs of operation in the long term. Copper coil corrosion is also a likely problem, especially in coastal or wet regions. There should be regular maintenance like fins cleaning and inspection to guarantee proper functioning of these systems.

Looking Ahead

The choice between microchannel and traditional water coil heat exchangers boils down to your specific needs. If you’re designing a new, high-efficiency system with space constraints, microchannel technology is hard to beat. Its compact design and energy savings are tailor-made for the demands of modern applications. But if you’re working with an existing system or need something rugged for heavy-duty use, a water coil system might be the better bet.

As technology is progressing, we’re now experiencing the best of both worlds being merged in hybrids—microchannel-inspired designs with the ruggedness of traditional systems. Whatever you choose, having the positives and negatives of each will guide your decision. From my work with heat exchangers, I’ve determined that there’s no one size fits all solution—context matters.